Shrimp farm KTn Farm

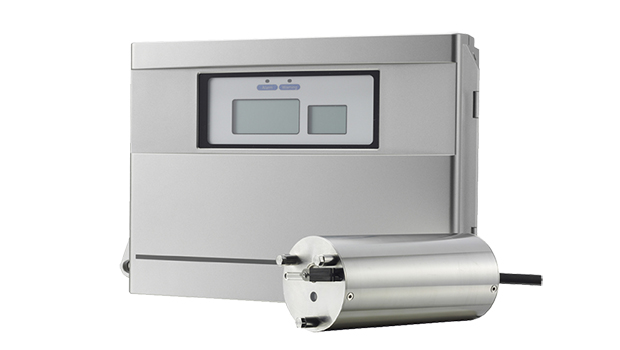

Optical Dissolved Oxygen Sensor DOS-20

We monitor the growth of shrimp by measuring the amount of dissolved oxygen in the water of the farm.

Thailand

- Automation

- Personnel-saving

- Operational-efficiency

- Facility-monitoring

- Water-conservation

- Inspection-reduction

- Building

- Sea-river-reservoir-dam