High-Sensitivity Turbidity Sensor Protects Beverage Quality and Reduces Purification Equipment Maintenance Loads

Real-time monitoring of well water turbidity and alarm output in the event of a malfunction

- Cost-reduction

- Operational-efficiency

- Facility-monitoring

- Inspection-reduction

- Fitness club, gym, sports facility

Correct assessment of water quality cannot be performed by simply relying on the initial impression that the water is clear.

Turbidity can occur due to a variety of factors, particularly in well water.

Well water is an important raw material for many beverage manufacturers, and even the slightest turbidity can cause problems in beverage manufacturing.

This article introduces some of the challenges in managing well water quality and the solutions made possible by a high-sensitivity turbidity sensor.

The Importance of Managing Well Water Quality

In addition to being used for mineral water, well water is a raw material for various beverages including coffee, juice, and beer.

Providing consumers with a stable supply of high-quality beverage products is impossible without proper water quality control.

One of the major concerns for well water is turbidity, which can happen due to a variety of factors.

Major Causes of Turbidity in Well Water

- Contamination from rainwater

Rainwater with surface dirt can flow into wells following a typhoon or heavy rain.

- Effects of earthquakes

Earthquakes can cause subsurface sand and soil to become mixed with well water. - Effects of civil engineering work

Civil engineering work near wells can cause vibrations during construction and excavation, resulting in subsurface sand and soil becoming mixed with the well water.

Problems Arising from Turbid Water

- Increased load on purification processes

High levels of impurities and solids can result in filters becoming more easily clogged, requiring more frequent maintenance and filter replacement, which increase costs. - Effects on disinfection processes

Microorganisms and viruses adhering to impurities in the water can lead to improper disinfection.

High-Sensitivity Turbidity Sensor for Reliable Monitoring of Slight Turbidity of Drinking Water Levels

Optex’s high-sensitivity turbidity sensor (TC-Mi) accurately measures even the slightest turbidity of drinking water levels, allowing for real-time monitoring of well water turbidity.

![Turbidity Sensor (Ultra Low Range) TC-Mi[Display][Parts No. 05297]](/e/solutions/e9j6q000000000ds-img/img-tc-mi-front.jpg)

Example Applications

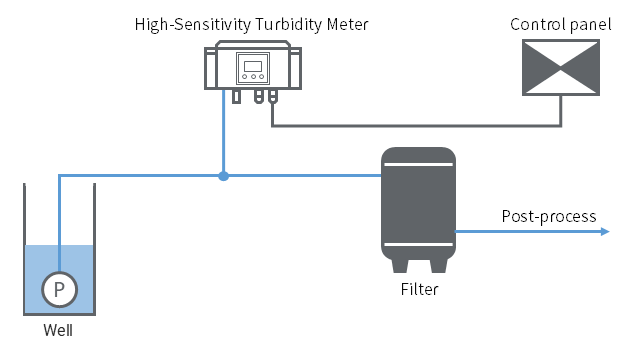

1. Water intake monitoring

If the high-sensitivity turbidity sensor detects that turbidity levels have exceeded predetermined levels in well water intake, an alarm signal is immediately output to the control panel, making it possible to turn the intake pump off.

This prevents filters from becoming clogged and minimizes purification problems, resulting in reduced maintenance and filter replacement frequency.

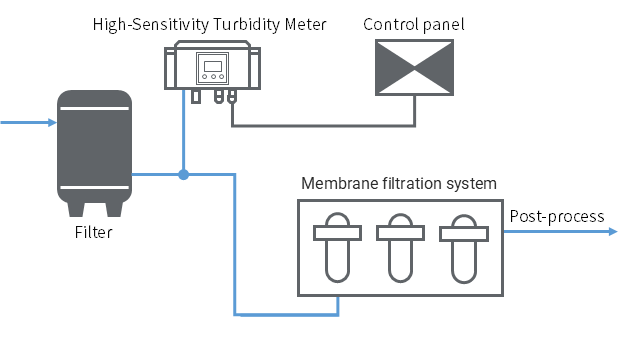

2. Filter media/filter maintenance monitoring

As filters age, the filter media and filters themselves begin to deteriorate, leading to clogging. This reduces water purification performance.

Using a high-sensitivity turbidity sensor to continuously measure the turbidity of water passing through the filter makes it possible to identify rising turbidity trends and properly manage the timing of filter media and filter maintenance.

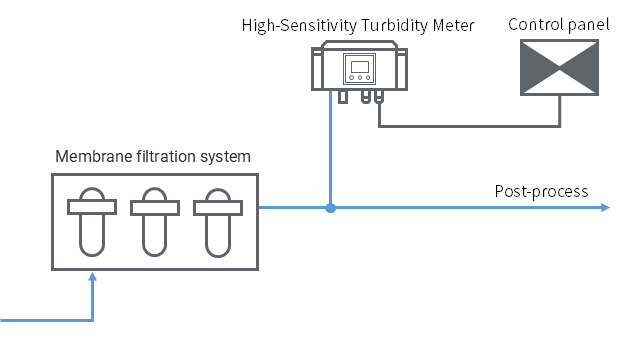

3. Membrane breakage monitoring

If the turbidity level of water being purified through a membrane filtration system exceeds the set turbidity level, it may indicate that the membrane has ruptured or some other problem has occurred.

In such cases, the high-sensitivity turbidity sensor can output an alarm to the control panel, automatically stopping the water supply to subsequent processes.

*1 Drinking water levels

In Japan, tap water is completely safe to drink. This is because tap water quality is based on the water quality standards set forth in the Water Supply Act.

The water quality standards include 51 items that focus on health effects, safety, taste, odor, and turbidity, which includes a specific safe turbidity level.

According to the water quality standards, the safe water turbidity level is 2 degrees.

Click here for more information on turbidity.

FAQ Turbidity

Photos are for reference only.

Visualization of turbidity can be affected by the background,

the way the light hits the water, and other factors.

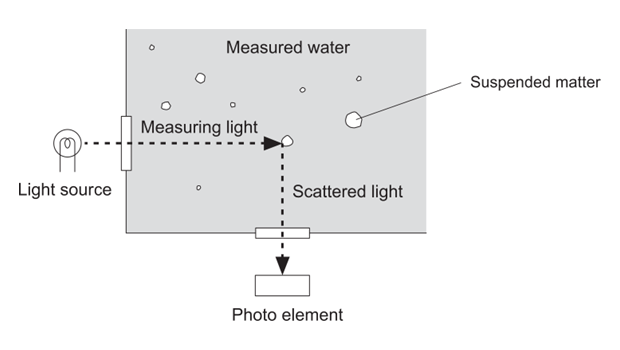

*2. Measuring principle of high-sensitivity turbidity sensor measurement: 90-degree scattered light method

Optex’s Turbidity Sensor TC-Mi uses a method of 90 degree scattered light.

In this method, a light source illuminates the surfaces of matter suspended in the water, and the light is scattered by these surfaces is detected by a photo element installed at an angle of 90 degrees from the light axis of the measured light. The turbidity is determined by the amount of the scattered light.

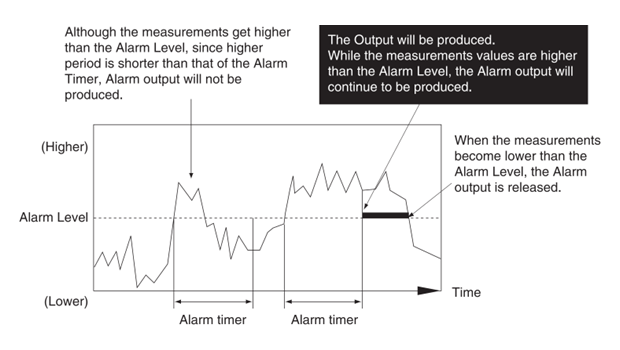

*3. Alarm level, Alarm timer

When the measurements get higher than the Alarm level continuously beyond the time set by Alarm timer, the Alarm output will be produced.

Product Informations

Related Informations

Contact phone number

- Headquarters

- +81-77-579-8680

Contact form