Notify replenishment at the optimal time

Easily convert the remaining amount in the tank to IoT

- Facility-monitoring

- IoT

- Factory-warehouse

- Farm

For example, if the raw materials and fuel required for production are insufficient and the production line or work is stopped, a large loss will occur. In order to solve these problems, the movement of remote monitoring using IoT is becoming active.

By automating the work that people have done so far using sensors and IoT technology, it is possible to reduce personnel (labor saving) and improve work efficiency by utilizing acquired data.

Patrol and check work in the tank remaining in the factory

The factory has tanks that store a variety of materials, fuels and lubricants. In order to check the remaining amount in the tank, it is common to make regular patrols to the site where the tank is located.

In the case of a factory on a large site, the tanks are often distributed in remote locations on the site, and it takes a considerable amount of time just to patrol. There are also safety issues, such as climbing high up to measure the remaining amount.

Also, if you manually record the calibration results, you may make mistakes.

Patrol and replenishment work of storage suppliers

Businesses that supply storage also make regular patrols to check and replenish the remaining amount. In many cases, this patrol replenishment work is based on past experience.

As a result, they may go to replenishment even though they have enough storage, and conversely, replenishment may be delayed even though there is a shortage of storage due to sudden increase in usage.

In this way, patrol and replenishment operations are often inefficient, reducing customer satisfaction and creating lost opportunities.

[Solution]

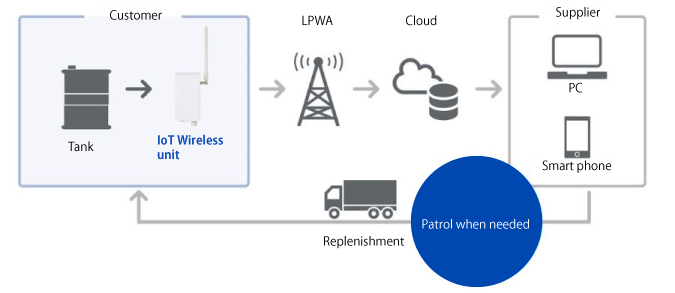

The remote monitoring solution for the remaining amount in the tank can manage the remaining amount in the tank installed in the factory from a remote location using IoT. This solution detects the remaining amount in the tank. The signal from the sensor is transmitted to the cloud by the IoT wireless unit to visualize the remaining amount in the tank. You can also email us when to refill your stock.

By remotely monitoring the remaining amount in the tank, labor-saving patrol, calibration, tabulation and replenishment work that relied on human labor can be achieved. There is no need to patrol to dangerous places such as high places, and safety can be achieved.

By visualizing the remaining amount, it is useful for business improvement such as inventory management and efficiency improvement of arrangement work. Furthermore, by analyzing the tendency of the remaining amount, it is possible to formulate an appropriate patrol route, reduce wasteful delivery, and reduce transportation Costa and labor costs.

Easy to install in existing tanks and ready to operate

Moreover, the communication cost is low

The IoT wireless unit can be connected to various sensors installed in the tank to detect the remaining amount. Since it can be easily retrofitted to the tank, it is possible to remotely monitor the remaining amount in the tank in a short period of time.

- Easy connection to existing tanks

It can be easily connected to an existing tank together with a sensor and can be immediately used as an IoT compatible device.

Moreover, if it is a battery-powered type, no major construction work is required.

The battery has a long life of more than 5 years. (Depends on the number of uses)

There is also an external power supply type that does not require battery replacement. - Wide area wireless network Sigfox compatible and low price operation

It uses the wireless communication standard Sigfox * 2 , which is one of LPWA * 1 . Sigfox has the features of low cost, power saving, and long-distance transmission. It can be operated at a lower price than conventional communication methods. - Design structure IPX5 that can be used outdoors

It is a highly waterproof structure for supporting IoT solutions in various fields.

You can use it outdoors with confidence.

* 1. LPWA (Low Power Wide Area):

A general term for wireless communication technologies that enable long-distance communication with low power consumption. It is attracting attention as an effective technology for IoT solutions because it can deliver radio waves to base stations that collect data while suppressing the current consumption of equipment.

* 2. Sigfox:

One of the LPWA communication standards for IoT. It is deployed in 60 countries, mainly in Europe and the United States, and Kyocera Communication Systems Co., Ltd. provides infrastructure construction and network services in Japan. Since the service started in February 2017, we have been building an area, and the population coverage rate will reach 90% in November 2018, and we are expanding the area aiming for 97% in the summer of 2019.

[Effects]

- Business efficiency

・ Real-time data collection by remote monitoring saves labor in tank patrol, calibration, and tabulation work.

・ Streamline inventory management and ordering operations by visualizing the remaining amount

・ By analyzing the remaining amount data, it is possible to formulate an appropriate patrol replenishment course and streamline delivery operations. - Improving productivity and working environment

・ Reduce labor costs by improving work efficiency

・ Use the spare time for different tasks

・ Reduces work in adverse environments such as dangerous high places - Achieves short-term introduction and low cost

・ Can be easily installed in existing tanks and can be operated immediately

・ Shortening the construction period and reducing construction costs with the IoT wireless unit

・ Sigfox reduces communication costs and reduces running costs

[Usage example]

Product information

IoT wireless unit

Associated information

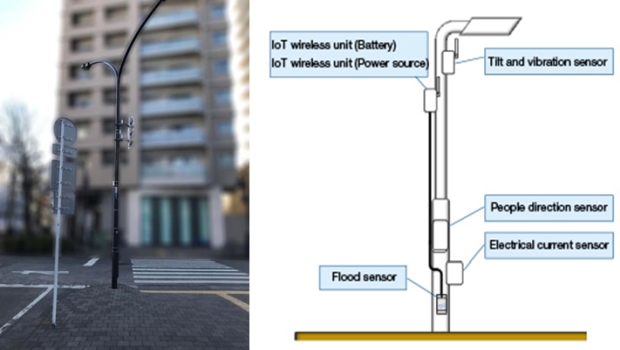

Optex Starts Verification of Monitoring the Flow of People, Flooding, and Equipment by Effectively Using Street Lamps in Suginami Ward

- IoT, Safety, Disaster prevention, Town development, Remote monitoring, Facility monitoring, Visualization, People direction sensor, Electrical current sensor, Tilt and vibration sensor, Flood sensor

Contact phone number

- Headquarters

- +81-77-579-8680

Contact form

Support information