Turbidity Sensor TC Series

Make turbidity check easier and more compact. And realize significant cost savings.

| Products Name |

|---|

| TC-100 [Sensor],[Parts No. 05035] |

| TC-500 [Sensor],[Parts No. 05036] |

| TC-3000 [Sensor],[Parts No. 05049] |

Features

● Built-in wiping cleaning system certainly keeps lenses clean.

Check and clean the window surface once every month.

● "Easy to clean" scratch-proof sapphire glass applies to the optical windows.

The optical windows are made of hard-to-scratch sapphire glass. It enables you to scrub the windows surface without problems.

● Compact size can fit into any installation site.

The compact design makes it possible to install any places.

● Continuous measurements can be achieved by installing only one censor.

Built-in analog output function covering 4 to 20 mA is incorporated, which makes it possible to transmit data to various equipment according to your applications.

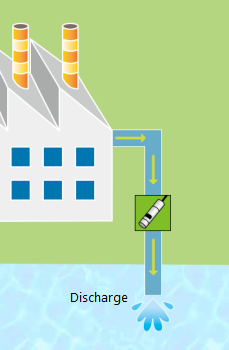

Applications

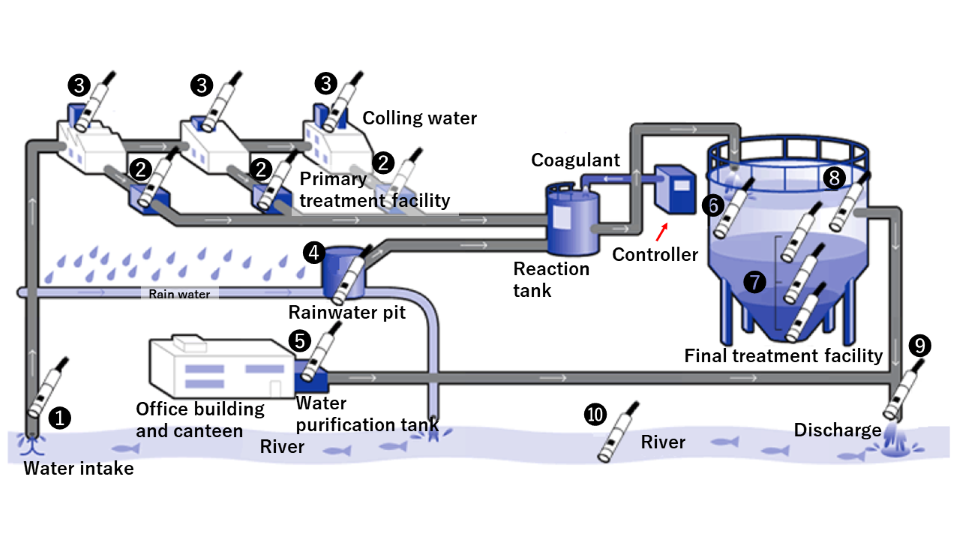

The TC-100/500 can be installed at various sites throughout the factory.

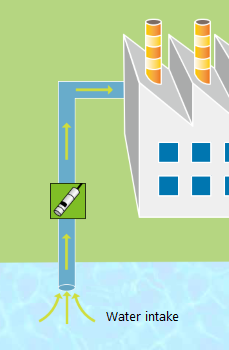

1.Monitoring acquisition of water for factory use

By monitoring the turbidity of the water when it arrives, we can prevent trouble in the event that there is a sudden shift in turbidity down the line.

2.Turbidity monitoring at each stage in the manufacturing process

This facilitates easy pinpointing of where the problem started in the event that an abnormality occurs in wastewater treatment.

By monitoring the primary treatment facility, we can achieve more stable operation of the final treatment facility.

3.Turbidity monitoring at the cooling tower

It is possible to control the operation of the water filtration equipment and adjust the blow water volume according to the turbidity monitoring concentration after applying a cleaning agent.

4.Rainwater pit

This allows valve control to deliver only high-concentration initial rainwater to the treatment facility and run water into the river at the point treatment is no longer needed.

5.Monitoring drainage outside the manufacturing process

We can achieve total management of a factory’s wastewater by monitoring not only the water used in the manufacturing process but also that used in the purification tank, etc.

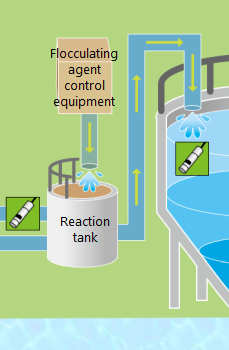

6.Coagulant control

By firmly establishing the correct concentration of wastewater, we can insert the appropriate amount of cleaning agent, allowing us to achieve a stable water quality.

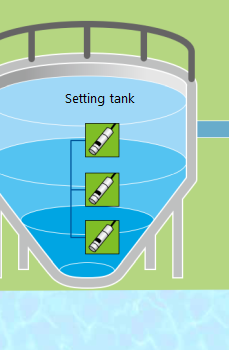

7.Sludge interface check

By attaching a sensor to the settling tank, the sludge interface can be monitored.

Setting sensors up in two or three different stages creates a more accurate picture of the interface.

8.Monitoring of sludge overflow

We can perform functions like monitoring overflow of sludge, halting the drainage of water, and returning it to the raw treatment water.

9.Monitoring of water outflow

This allows for final monitoring of the treated water as flows out into the river.

10.Remote monitoring of turbidity in rivers

By combining our sensors with NiGK Corporation’s solar-panel-mounted “aqua e monitor,” we can remotely observe even places such as rivers, where an electric power supply can’t be secured.

(Measurement data is sent by e-mail.)

Options

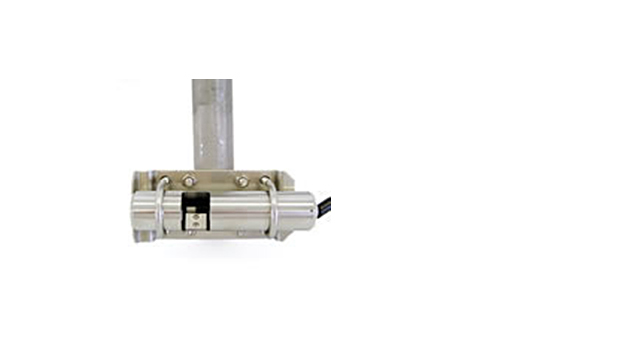

Mounting Attachment: TA-1

[Parts No. 05039]

By mounting the turbidity sensor and SS sensor to the pipe, it prevents hitting the wall or facility equipment and rotating it. Please use it when the water current is fast.

Applicable pipe: Stainless steel pipe for piping 25 A (OD 34 mm)

Material: S30400

*Please prepare the pipe for installation by customer

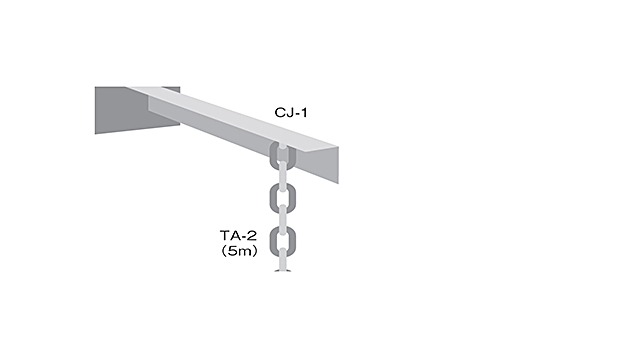

Support bracket: CJ-1

Hanging chain: TA-2

CJ-1 [Parts No. 05033]

TA-2 [Parts No. 05067]

It is a metal fitting for hanging the sensor.(CJ-1)

It is a chain for suspending the sensor.(TA-2)

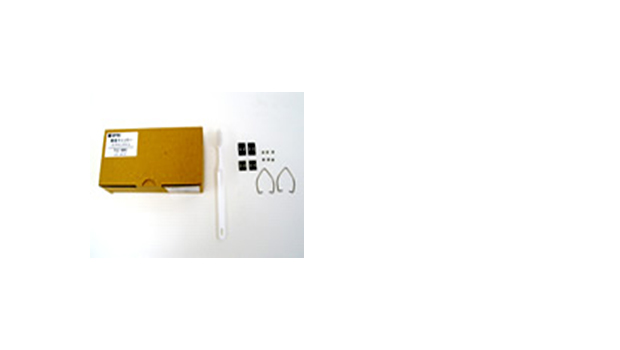

Maintenance kit: TC-MK

[Parts No. 05038]

It is a replacement blade of the wiper cleaning device. Please exchange once a year as a guide.

Component

●Wiper blade × 2

●Cleaning brush × 1

●Detection window Cleaning paper × 2

●Manual × 1

Specifications

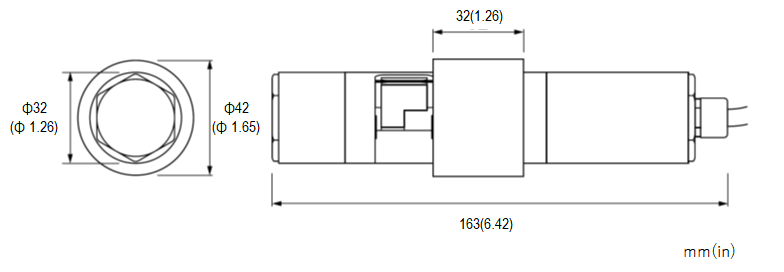

Dimensions

Detector

| Model | TC-100 | TC-500 | TC-3000 |

|---|---|---|---|

| Measuring range | 0-100 (FTU) | 0-500 (FTU) | 0-3000 (FTU) |

| Power supply | 12 DCV ±10% | ||

| Power consumption | At regular operation: 30 mA (Max.), At cleaning operation: 240 mA (Max.) (excluding analog signal output) | ||

| Output | Analog (4-20 mA) signal output: resistance load of 300 Ω (Max.) 4 mA: 0 FTU 20 mA: 100 FTU (TC-100), 500 FTU (TC-500), 3000 FTU (TC-3000) Self-checking output: open collector (12 VDC 20 mA Max.) |

||

| Input | Calibration signal input | ||

| Cleaning system | Both sided swing wiper cleaning system | ||

| Time interval for cleaning | Clean once immediately after power-on, andsubsequently clean once every 30 min. | Clean once immediately after power-on, and subsequently clean once every 10 min. | |

| Operating temperature | 0 to +40°C (unfrozen) | ||

| Major material | SUS316L, Sapphire glass, Fluorocarbon rubber, EPDM, POM | ||

| Dimensions | Φ32 x 163 mm (Φ1.26 x 6.42 in) (excluding horizontal hanging attachment) | ||

| Weight | Approx. 930 g (Approx. 2.05 lb) | ||

| Degree of protection | IP68, maximum depth of 2 meters (underwater type) | ||

| Detector cable length | 10 m | ||

Detector TC-100/TC-500/TC-3000

Contact phone number

- Headquarters

- +81-77-579-8680

Contact form

Support information