Deterioration of Overhead Signboards: A Risk That Lurks in Plain Sight of Us All

- Prevention

- Cost-reduction

- Facility-monitoring

- IoT

- Inspection-reduction

- Building

Signboards set up in high places outside are daily subjected to sunlight, wind, rain, and snow, and these gradually eat away at them. On top of that, damage due to salt damage and natural disasters such as earthquakes, as well as deterioration that comes from many years of continuous use, can cause the affixed parts to loosen or crack, and ignoring these problems invariably leads to tilting or collapsing.

These signboards appear countless to anyone who has looked up while walking through busy shopping districts or major urban centers. It may be difficult to believe that these signs could fall down from above, but such incidents have been happening more and more all over Japan.

For this reason, the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) has established guidelines regarding safety inspections of outdoor noticeboards and the like, and various local governments have also laid out ordinances regulating such materials, but the fact of the matter is that at present there is no firm method of inspection beyond simple visual examination.

Don’t Let Looks Deceive You: Use Daily Data to Monitor Changes

In order to foresee and prevent collapsing signboards, regular inspections are what is required. This applies not only to old signboards, because even new ones can, as a result of natural disasters and the like, become bent over or have their screws come loose. In such cases they may seem to be fine, and visual inspection may not be enough to notice the problem. The inside of the signboard is also deteriorating over time, without being clearly visible. It is an extremely big ask to have all the numerous signboards that dot the landscape checked at all times. And there is another problem: relying on the people who paid for the signboards to perform the visual inspection raises serious issues of objectivity in determining whether degradation has taken place, and not a few people will question such inspections’ accuracy.

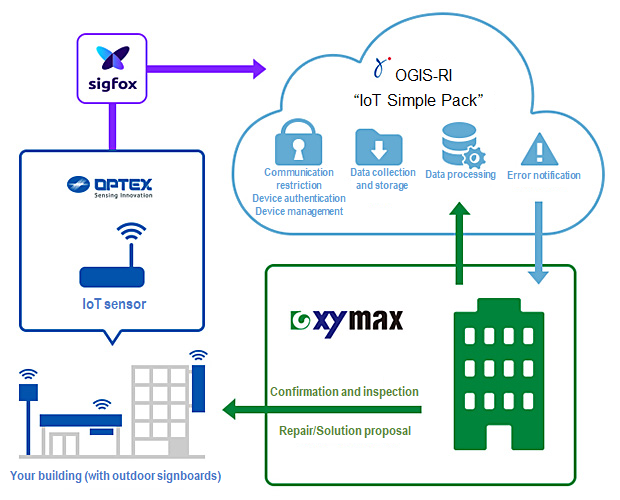

Optex’s IoT sensors provide the answer! Just by attaching the sensor to the signboard it will measure any tilting and/or vibration, and automatically send regular status reports and change data. It can be utilized as a reliable tool to determine when there is any kind of problem.

The IoT sensors were developed for use on signboards, and, being compatible with Sigfox, one of the standards for LPWA wireless communication technology, allow for easy construction of a remote surveillance system.

Greatly Cutting Down on Costs and Labor of Large-Scale Inspections

The most troublesome aspects of inspection are the cost and the workload. When it comes to inspection of signboards installed in high places, the inspection cost will be only about 10,000 yen if all that is needed is to look at it with binoculars from below, but the cost jumps to more than 100,000 yen if an elevated work vehicle is required.

Securing an elevated work vehicle, dispatching both an inspector and a traffic conductor, making a request to the police and local authority, and so on all increase the cost and workload involved in the inspection. This puts a massive burden on companies responsible for a large number of signboards at volume retailers and restaurant chains.

It is possible to leave the signboard inspection work to IoT sensors, allowing for remote monitoring of the signboards’ status and significant reduction in the cost and workload. Let’s use sensors to create a scheme where we check the daily data updates, and only perform inspections on those signboards where inspections are needed! Furthermore, our IoT sensors are battery-powered, and the batteries need only be changed once every five years, allowing the sensors to be used over an extended period of time. (This depends on the intensity of use, of course.)

Effectiveness

- By simply minimizing the risk of signboards falling, you can protect your corporate brand.

- Thanks to remote surveillance by the IoT sensors, cost and labor required in inspections are dramatically decreased.

- Because measured, relative, and objective evaluation is facilitated, decisions regarding the inspection period, changing time, and so on are also made clear.

Providing Total Support Service

—Inspection, Maintenance, and Monitoring—for Signboards

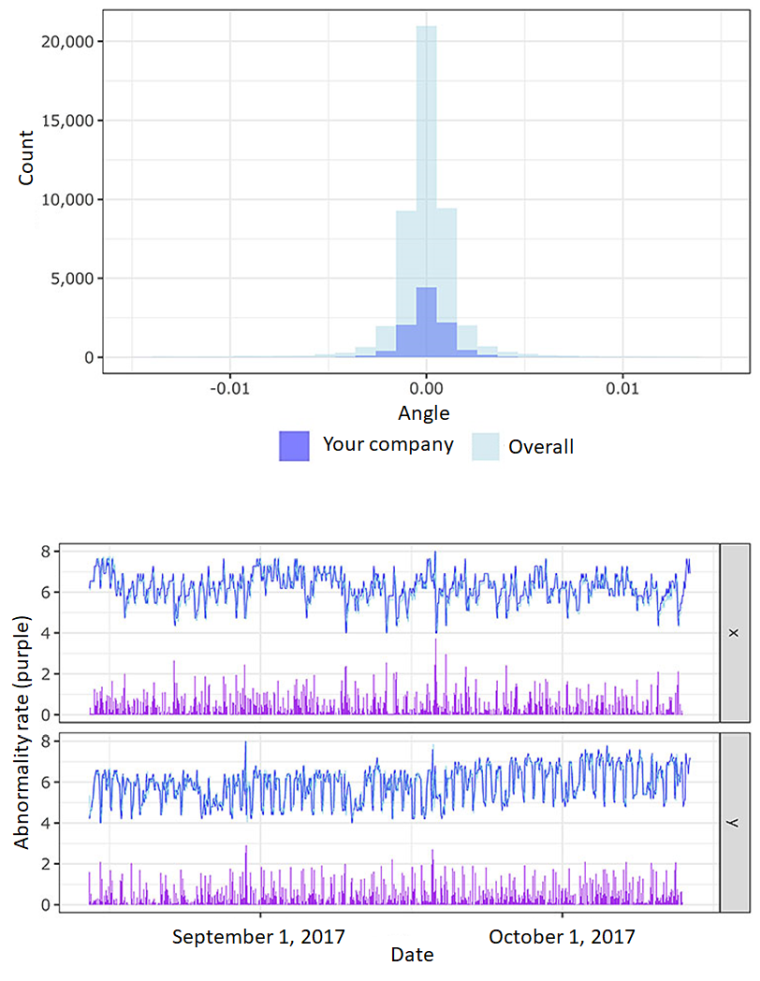

More and more companies are using Optex IoT sensor data for conservation inspection and maintenance control of signboards, to prevent major collapsing incidents before they happen.

The information that can be acquired from this data is used for everything from day-to-day signboard abnormality observation and maintenance planning, to effective inspection and repair proposals. If there is an abnormal change from the status quo, due to unforeseen circumstances such as a typhoon or earthquake, causing an increased risk of the signboard falling, our sensors allow for new maintenance and management services, such as speedy measures to immediately address the issue.

Sensing Precision to Increase Service Quality

Signboards come in all shapes and sizes, with some being mounted on walls and some jutting out from them like in the image at the top of this page. We perform field tests to take into account such issues as the shape of the signboard, what kind of place it is installed in, how measurement data is to be transmitted, as well as issues like workability and durability. By combining Optex’s sensing technology with our partner companies’ technical know-how, we can ensure usefulness from a wide variety of standpoints.

Case Study: Xymax Corporation

Inspection, Maintenance, and Monitoring Services

Xymax Corporation, a big name in the facilities management field, employs remote monitoring of tilting and vibration of signboards using Optex’s IoT sensors, and in October 2018 officially began “inspection, maintenance, and monitoring services” intended to proactively prevent falling or collapse.

Product information

Contact phone number

- Headquarters

- +81-77-579-8680

Contact form